Making a PVC ballet barre is a cheap alternative to buying one, but a single PVC barre can be pretty lightweight and unsteady on its own and the feeling of plastic underneath your fingers doesn’t give you that real studio feel. So instead why not add a length of wood instead of PVC as the handrail for your DIY home ballet barre?

There are some different ways you can approach making a PVC and Wood DIY barre. For this tutorial I have opted to use 1.5″ drainage pipe as the wooden dowel I found in the lumbar aisle fit so well inside the fittings. But if you are unable to find the perfect fit like I did or if you are after some alternative ways of making your barre check out the DIY Ballet Barre Homepage here for more tutorials including barres made from galvanized steel and double ballet barres.

STEP BY STEP INSTRUCTIONS – HOW TO MAKE A DIY SINGLE BALLET BARRE

For a pdf printout with a list of the tools, materials and cuts you need to make as well as a small diagram and simple instructions click here to join our newsletter. This way you have access to the member vault with all my free printables and more!

- Step 1: Gather your tools and materials.

- Step 2: Cut your PVC pipe

- Step 3: Assemble the fittings, Wood and PVC pipe

- Step 4: Screw and Drill the wooden barres in place

- Step 5: Secure the rest of the fittings together with a rubber mallet, glue or screws

- Step 6: Paint your PVC and oil or varnish your wood barre.

- Step 7: Your DIY Ballet Barre is ready to use!

- DIY Ballet Barre E-Book

- ALTERNATIVE DESIGNS

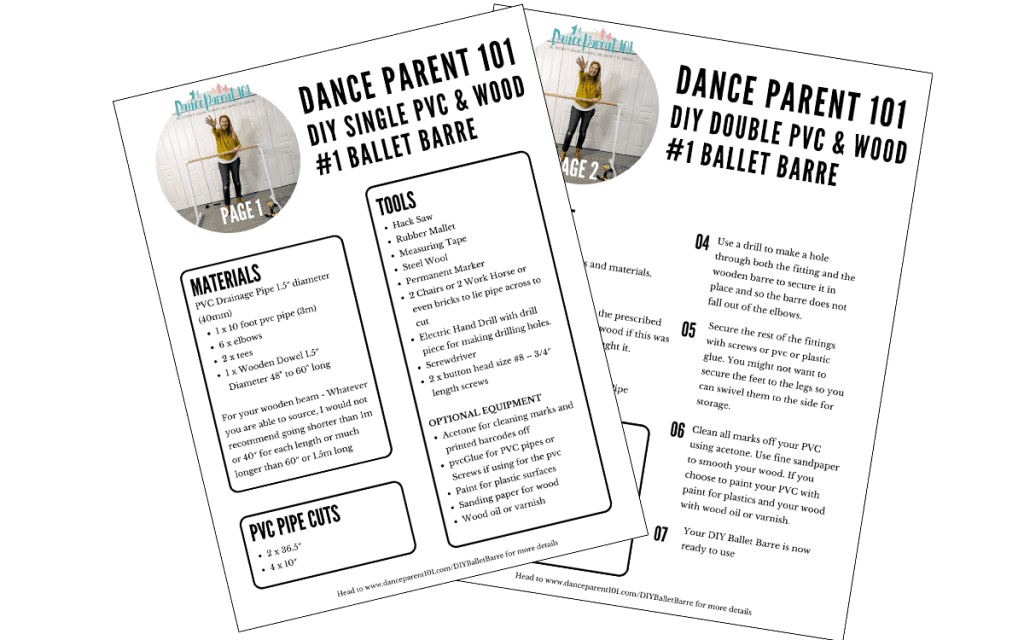

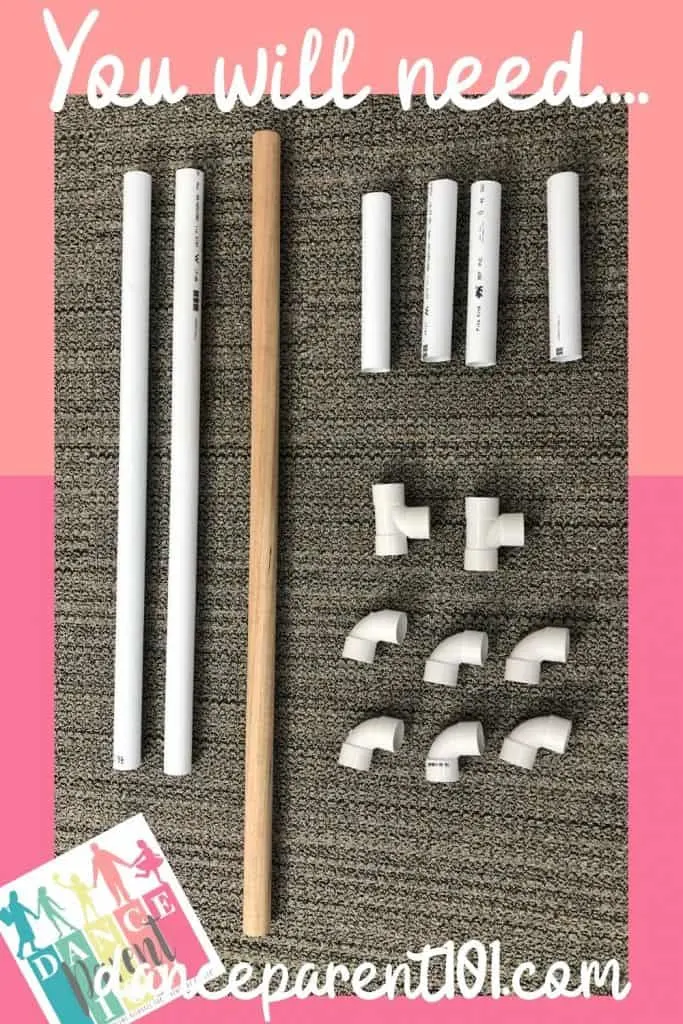

Step 1: Gather your tools and materials.

WHAT YOU WILL NEED

TOOLS or EQUIPMENT:

- Hack Saw

- Rubber Mallet

- Measuring Tape

- Steel Wool

- Permanent Marker

- 2 Chairs or 2 Work Horse or even bricks to lie pipe across to cut

- Electric Hand Drill with drill piece for making drilling holes.

- Screwdriver

- 2 x button head size #8 – 3/4″ length screws

OPTIONAL EQUIPMENT - Acetone for cleaning marks and printed barcodes off pvc

- Glue for PVC pipes or Screws if using for the pvc

- Paint for plastic surfaces

- Sanding paper for wood

- Wood oil

MATERIALS

- PVC Drainage Pipe 1.5″ diameter (40mm)

1 x 10 foot long (3m) - 6 x elbows for drainage pipe 1.5″

- 2 x tees for drainage pipe 1.5″

- 1 x Wooden Dowel 1.5″ Diameter (please read ALL notes below on buying your timber barre to get the right sizing!)

My wooden barre was only sold in two lengths 1.2m or 2.4m which is approximately 48″ and 96″ respectively and so to make the project cheaper I bought the shorter length. Feel free to purchase your wooden barre up to 60″ in length if available!

Another IMPORTANT note on buying your timber dowel. PVC fittings and timber dowel are not made to fit perfectly into each other. You may find that you can’t find exactly 1.5″ for the width of your wooden barre – but slightly larger or smaller because that is how they manufacture it. Also 1.5″ is usually the measurement of the inner hole of the pipe and not the entire diametre and so the hole in the fitting will be bigger than 1.5″ to accommodate the PVC casing. I have stated in the materials list to buy 1.5″ timber just to give you a measurement to begin with and look for because it will be smaller than your fittings and will fit, but you might find something that fits more snuggly in store!

In any case, make sure you carry your fittings with you to the timber section of your hardware store and slide them onto the timber to get your perfect fit. My timber was 42mm which when you transfer to inches is actually 1.65 inches and it slid in perfectly into the drainage pipe fittings! You want to ensure your wooden dowel is smaller and not bigger than your fitting as you will be screwing the wood in and so if it is smaller you will just end up with some space in the fitting which is fine after you have secured it with a screw from underneath rather than on top as I do in this tutorial!

Step 2: Cut your PVC pipe

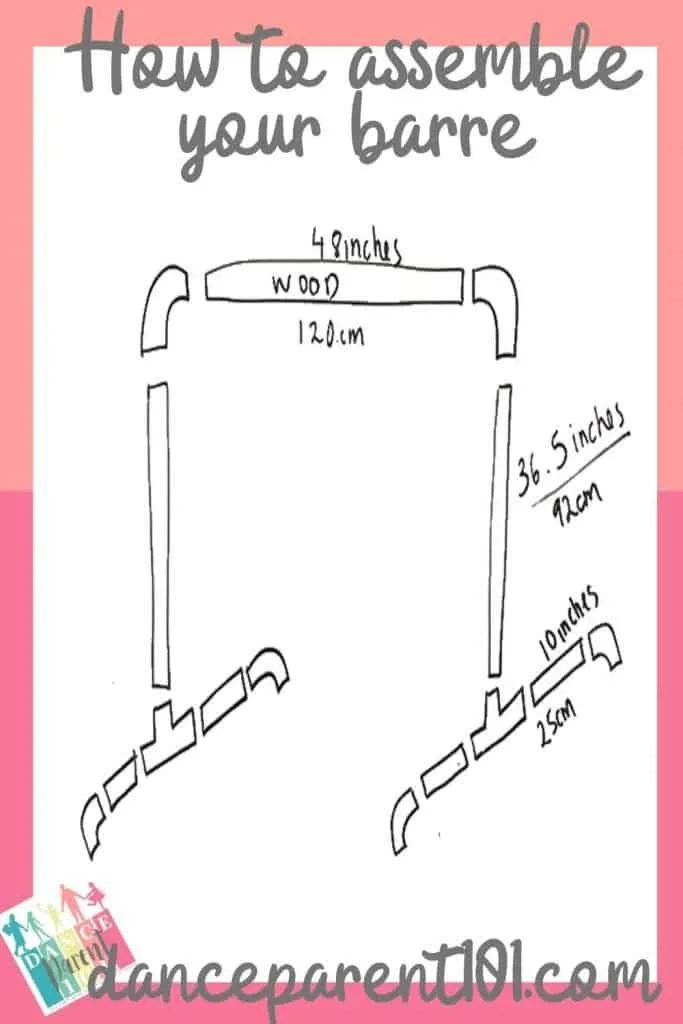

For this DIY ballet barre you will need to cut your PVC pipe into the following lengths:

- 4 x 10″ (4 x 25cm)

- 2 x 36.5″ (2 x 93cm)

You need a total of about 9.5 feet (Just under 3m), so you should have a little leftover at the end, but I advised to by a 10 foot or 3m length as this is usually what is sold in store.

HOW TO CUT PVC?

If your hardware or plumbing supply store can’t make the cuts for you and you have access to a miter saw and know how to use one – then go ahead and use that. If you have no idea what a miter saw is or how to use one, don’t worry, I didn’t use one.

I used a simple hacksaw and the video above shows you exactly how I did it. I simply measured a length I needed, marked this with a permanent marker and laid the pipe onto a couple of chairs for support, and then used the hacksaw to cut the pipe where I had marked. Use steel wool to quickly clean the cut edge of debris.

You can also use this same technique to cut your wood if needed – my wood was sold at precut lengths. As the wood is substantially heavier and harder to cut through than PVC I would advise having the wood held more securely in clamps or by a vice attached to a sturdy work table or something similar before attempting to saw it to your prescribed measurements.

TOP TIP: HOW TO PUT PVC FITTINGS ON THE RIGHT WAY

When using drainage pipe fittings it is really important to make sure your tee fittings mirror each other to face the same direction on either side of the barre. If you have watched my video, I explain how both tee fittings used to make the feet need to have their 88-degree angle facing the same way.

Drainage pipe fittings have 88-degree angles so that water is able to freely flow downwards. Because of the way they are made to accommodate this angle, the length on both sides of the tee outlet is not the same one is shorter and the other is longer. If they are fitted onto your barre the wrong way as shown in the image below, your barre will be unstable and could even result in an uneven barre.

Step 3: Assemble the fittings, Wood and PVC pipe

The image above should hopefully give you a good visual on how to on how to build this approximately 41″ tall ballet barre. The video gives you a step by step walk through of how to do it as well. But for all those who like to read instructions rather than watch them I will do my best to explain it step by step here.

Start with the feet.

Grab one elbow fitting and attach a 10inch piece of pipe to each horizontal opening. Put a tee fitting on the other opposite end of each pipe. The single opening of the tee should face upwards and the two elbows downwards. You should be able to stand this structure now on the floor. Follow these instructions to create another foot exactly the same and place it about 3 feet away from the first barre foot you made.

Insert the legs

Insert one of the 36.5″ pipes into the tee fitting that is facing upwards on one of the feet.

At the other end of the 36.5″ pipe push on an elbow so that the opening faces towards where you assume the other leg of the barre is going to go. Follow these instructions again and make the leg for the other side of the barre.

Insert the Barre

Insert the wooden barre into one of the elbow openings and then into the other. You now essentially have a ballet barre, but the wood needs to be secured into the plastic elbows otherwise it will fall out.

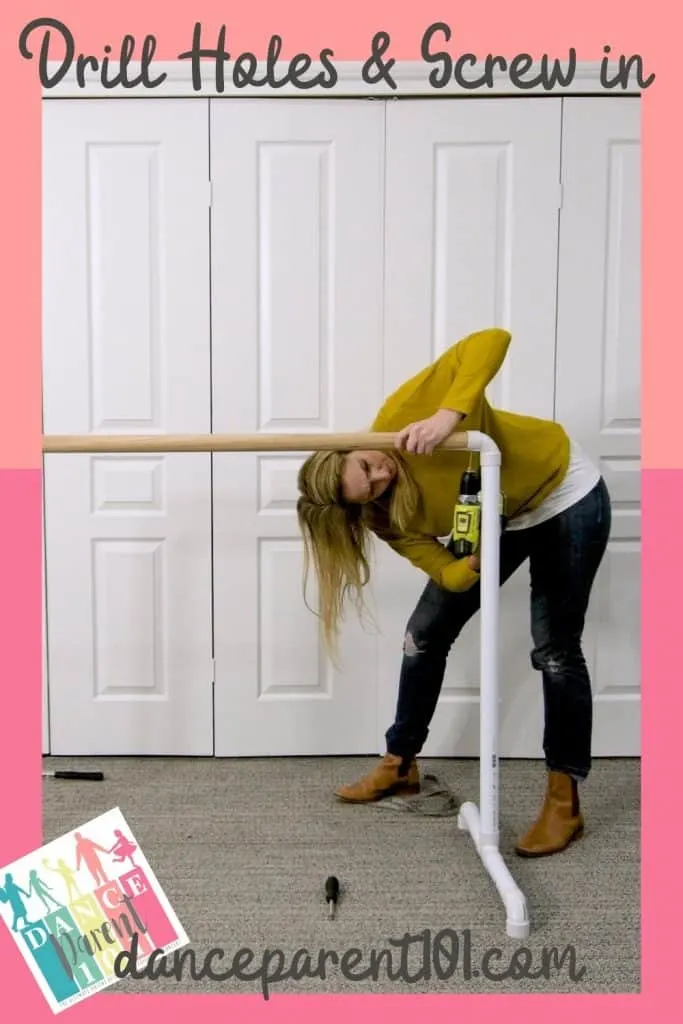

Step 4: Screw and Drill the wooden barres in place

Use a handheld drill, to drill a hole through the PVC elbow fittings where the wood is attached when the wooden barre is still inserted into each fitting. You want the hole to go through both the fitting and the piece of wood. I opted to make the hole under the elbow rather than on top to hide the screw. I also opted to make the hole while the elbow was still attached to the leg – you could un-attach the elbow from this and turn it upside down to make it easier to drill and screw!

Screw in by hand a size #8, 3/4″ inch button head screw to secure the wooden barred into each fitting.

Drilling a hole and then screwing a screw in by hand are just some measures I take to ensure I do not split the wood, as although this has not happened yet when making ballet barres it has occurred on some other projects when I did not take the same precautions.

Step 5: Secure the rest of the fittings together with a rubber mallet, glue or screws

I have to be honest, after ensuring the wood would not fall out by screwing them in, I kind of left this barre as it was without gluing or screwing together the rest of the pieces. Not that I would advise this because the feet keep coming apart, but a few hits with a rubber mallet does keep it together for a while.

I would advise if you are going to use this barre ofter and want it to be as sturdy as possible to use PVC or plastic glue to glue all the other fittings together or to use screws so you can pull it apart if you ever wanted to.

If gluing you might choose to not glue the legs into the feet so that you can swivel them to the side or take them off for storage. But this tends to make your barre a little less sturdy so if you have the space to leave your barre out, glue them in as well!

Step 6: Paint your PVC and oil or varnish your wood barre.

Most PVC glues will leave purple or green colored marks around the fittings. This is so plumbers know that plumbers glue, also known as PVC pipe glue, has been used and the fitting should be watertight. But as we are not running water through our pipes you might want to paint your barre to hide these. Use a paint made for plastics to do this and make sure you have removed the wood to ensure that you don’t get paint all over your barre.

If you used screws or a general clear adhesive for plastics you might decide to keep your ballet barre white or grey like the pipes you used. You may need to clean all the printed barcodes and identifiers off the pipes and you can easily do this with a cloth and some acetone. Some of my fittings also came with barcodes stuck on them and I had to use a special spray to get the gooey stickiness off them.

For your wood, you should sand it down with fine grade sanding paper and then either use wood oil or varnish to finish off your barre. This will help to ensure it stays smooth and does not splinter. It also makes it easier to clean and allows the hand to move smoothly along it.

Step 7: Your DIY Ballet Barre is ready to use!

Once hammered together, or glued and painted and dry your ballet barre is ready to use. Just remember Ballet Barres are used for balance and for stretching not for hanging off or for gripping.

DIY Ballet Barre E-Book

Why try and work it all out on your own, when I have gone and compiled everything you need to know about making a DIY Ballet Barre into a book! Check it out the e-book where we have newly designed instructional manuals, tips and advice as well as links to the video tutorials, all in one location.

ALTERNATIVE DESIGNS

If this particular ballet barre isn’t what you were after check here for the DIY Ballet Barre home page where I have instructions on how to make double ballet barres, barres from galvanized steel, and others using wood. I also have a few suggestions on different styles of feet as well as on how to weigh down your barre so it doesn’t move or what to put under the feet so they don’t scratch wooden floors.