Building a single ballet barre from PVC is super simple and a really cheap solution that can make doing ballet and dance practice from home much easier than using a chair, bench or table.

The great thing about this barre is that it is really customizable. I personally feel it is a good height if you follow my measurements your barre will end up being 41″ in total height and 60″ long. I am around 6’8″ and this height is great for me as well as for my eldest who is ten. But if you are taller just add on a couple of extra inches to the legs. If you are shorter than make the barre as I have explained and then once assembled simply cut back however many inches on both legs until you are happy with the height. Secondly, I wouldn’t advise going too much longer on the barre length for stability reasons, but if you wanted to add on another few inches do so before cutting, but if it is too long, then just cut it back to size!

Lastly, if you are actually wanting to make a double barre or perhaps one with a PVC frame but with a wooden barre or one using no tools and from galvanized steel pipe, I have made those as well and you can look at the instructions and video tutorials for any of these from my DIY Ballet Barre Home Page which will open up in a new tab or browser page when you click here!

STEP BY STEP INSTRUCTIONS – HOW TO MAKE A DIY SINGLE BALLET BARRE

For a pdf printout with a list of the tools, materials and cuts you need to make as well as a small diagram and simple instructions click here to join our newsletter so you can access the newsletter member area with free printables and more!

- Step 1: Gather your tools and materials.

- Step 2: Cut your PVC pipe

- Step 3: Assemble the fittings and PVC pipe

- Step 4: Secure the fittings together with a rubber mallet, glue or screws

- Step 5: Paint your PVC Ballet Barre

- Step 6: Your DIY Ballet Barre is ready to use!

- DIY Ballet Barre E-Book

- ALTERNATIVE DESIGNS

Step 1: Gather your tools and materials.

WHAT YOU WILL NEED

TOOLS or EQUIPMENT:

- Hack Saw

- Rubber Mallet

- Measuring Tape

- Steel Wool

- Permanent Marker

- 2 Chairs or 2 Work Horse or even bricks to lie pipe across to cut

OPTIONAL EQUIPMENT - Acetone for cleaning marks and printed barcodes

- Glue for PVC pipes or Screws if using

- Paint for plastic surfaces

MATERIALS

- PVC Pressure Pipe 1.25″ diameter (32mm)

1 x 20 foot long (6 meters)

OR

2 x 10 foot long (3 meter) PVC Pressure Pipe - 6 x elbows for pressure pipe 1.25″

- 2 x tees for pressure pipe 1.25″

You are going to need a total of 173 inches plus a little extra to factor in pipe degradation when you cut it, so let’s say 175 inches of pvc pipe which is about 15 feet. If you can buy your pipe by the foot, you only need to get 15 feet or 4.5 meters in total for this barre. But generally you will find that hardware and plumbing supply stores sell PVC pipe in the pre-cut measurements listed in the materials list.

If your store is willing to cut the pipe for you give them the cutting measurements I outline below.

What type of PVC pipe should I use?

For this barre, I have use fittings that have 90-degree angles. In Australia, this type of pipe is called pressure pipe or CPVC and is used to plumb hot tubs and sprinklers or irrigation systems. It is best to use this type of pipe for your ballet barre to create right angles which create a sturdier, stable, and more level barre. Drainage pipe on the other hand that is used in the plumbing in houses has fittings with an 88-degree angle so that water can more easily slide down through the pipes using gravity. Drainage pipe is fine to use, but you will notice that your barre is not at as level and that the fittings strain slightly as you fit everything together.

What diameter pipe is best?

For this particular ballet barre, I have used 1.25″ or 32mm diameter PVC pressure pipe as I found the width of this pipe felt best under my hand and wasn’t too wide for my kids either. If you are unable to get 1.25″ I have seen other tutorials where 1.5″ or 40mm PVC pressure pipe was used so it will be ok just a little chunkier.

If you are using drainage pipe (refer to the previous point about which type of pipe you should use) 1.5″ has the around the same size outer diameter as 1.25″ pressure pipe anyway (Pressure pipe is thicker and stronger than drainage pipe which is why the smaller pressure pipe is a similar size to the larger drainage pip).

Step 2: Cut your PVC pipe

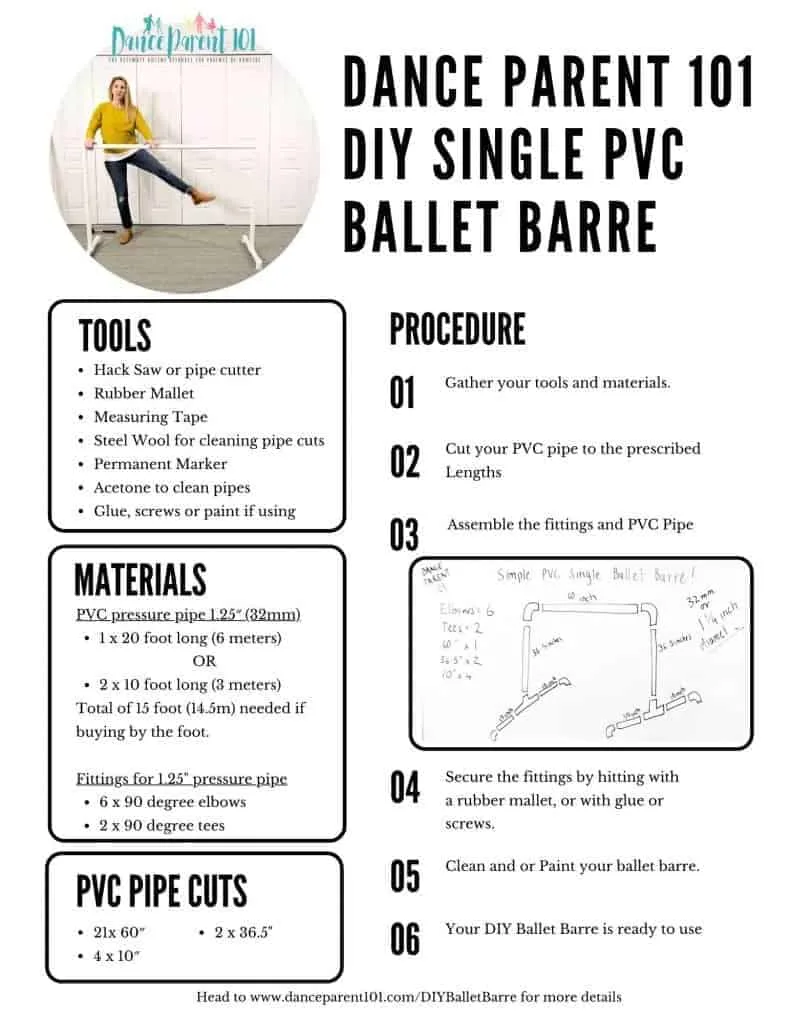

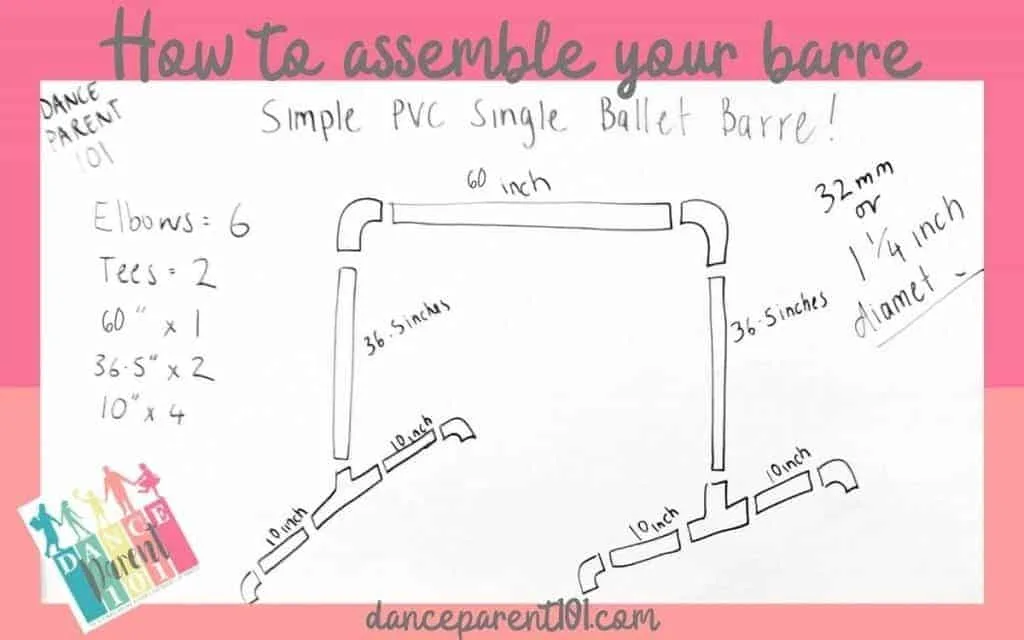

For this DIY ballet barre you will need to cut your PVC pipe into the following lengths:

- 1 x 60″

- 4 x 10″

- 2 x 36.5″

Whether you buy your pipe in one long 20 foot (6 meter) length or two 10 foot (3 meter) lengths it shouldn’t matter in what order you cut your pipe, because when making a single barre you will have pipe left over. Just to be sure, start with the longest pieces first to ensure you get those lengths from your pipe.

‘If your hardware or plumbing supply store can only cut your 10-foot pieces of pipe into half lengths to fit into your car – that is fine – this means you will end up with four 60″ pieces and you need 1 piece this length for your barre anyway and that just means one less cut for you to do at home!’

HOW TO CUT PVC?

If your hardware or plumbing supply store can’t make the cuts for you and you have access to a miter saw and know how to use one – then go ahead and use that. If you have no idea what a mitre saw is or how to use one, don’t worry, I don’t know how to use one either and just used a simple hacksaw. I know that using tools and DIY is not for everyone and so I made a blog post and video tutorial on how to easily cut your PVC for those who needed it which you can view here!

Simply put, I marked my first measurement on my PVC pipe which I then laid on a couple of chairs and then used a hacksaw to slice through the pipe where I had marked it. Once cut, I would use steel wool to clean off all the little pieces of PVC that clung to the edges of the pipe. Through trial and error I found steel wool to be much more effective than sandpaper for this cleaning job!

Once you have cut your pipe into the right lengths and have all your fittings grab your rubber mallet and you can start assembling your barre. (If you don’t have a rubber mallet – mine was less than $3 at the store!!! you could use a hammer with something soft wrapped around the head to stop if from cracking your pipe.)

Step 3: Assemble the fittings and PVC pipe

The image above should hopefully give you a good visual on how to put all the pieces together and the video gives you a step by step walk through of how to do it as well…..but if you would like to read the instructions, on how to build this 41″ tall ballet barre keep on reading here.

Start with the feet.

Grab one tee and push in a 10″ piece of pipe on each horizontal opening of the tee. With the third tee hole facing upwards, place an elbow on the end of each piece of pipe. Push the elbows on so they are angled downwards – or opposite to the tee to create the feet – it should be able to stand up on the floor now. Follow these instructions to create another foot exactly the same and place it about 3 feet away from the first barre foot you made.

Insert the legs

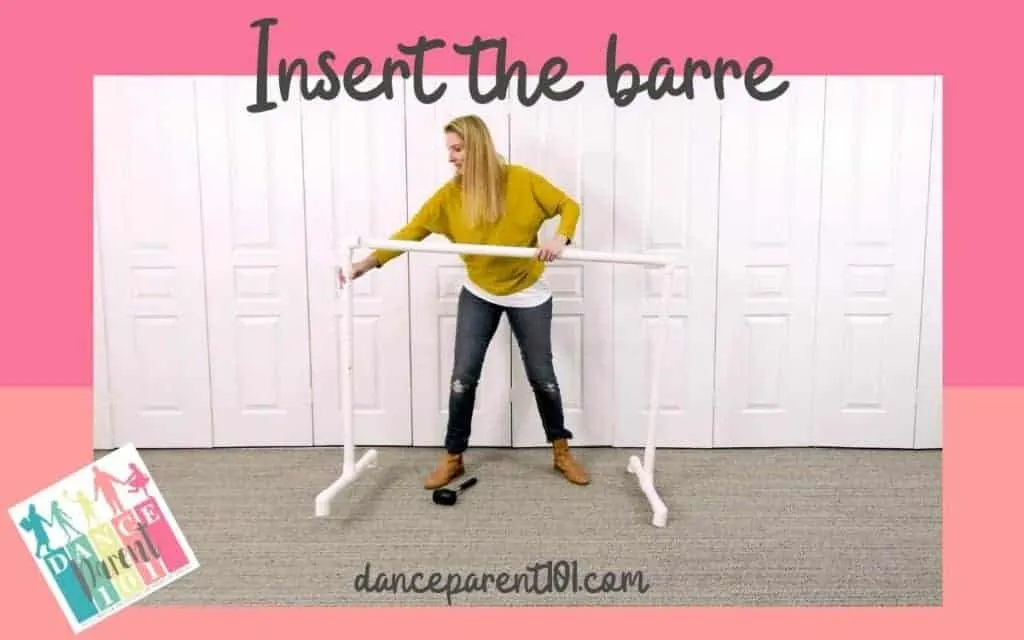

Insert one of the 36.5″pieces of pipe into one of the feet where there is an opening of the tee fitting. At the other end of that pipe place an elbow. The opening of the elbow should be in the direction of the other foot you made. Put the other 36.5″ leg into the other foot and place the last elbow ontop of the pipe so that it’s opening is facing the opening of the other elbow.

Add in the barre.

Insert the final 60″ length into each of these openings to finish off the barre.

Step 4: Secure the fittings together with a rubber mallet, glue or screws

Next you need to decide how you want to secure your barre. For now you might just want to hit all the pieces together with a rubber mallet and use it and make sure you are happy with the height and length of all the peices. But you will eventually want to secure it with glue as the pipe will tend to come out of the fittings when you use it which can be dangerous and annoying!

You have several choices when securing your barre because the pipes are not being used to transport water. I will have video up very soon about the different options you have, but the two most common ways would be using the glue plumbers use to secure pipes or drilling holes and using scres to hold the pieces of pipe together.

Step 5: Paint your PVC Ballet Barre

If you have gone ahead and used speciality plumbing glue to fix your ballet barre together you will most probably find that the glue has seeped out of the joints and is visible creating purple or green (depending on the color of your glue) drip marks around the pipe joins. In this case you are most likely going to want to paint your barre so that it looses its DIY look and feels polished and professional. When choosing a paint make sure it is made for plastics so that it doesn’t peel off easily.

If you used screws or a clear adhesive for plastics you might decide to keep your ballet barre white like the pipes you used. You still may want to clean all the printed barcodes and identifiers off the pipes and you can easily do this with a cloth and some acetone. Some of my fittings also came with barcodes stuck on them and I had to use a special goo be gone spray to get the gooey stickiness off them. You can check this all out in the video and article I wrote here about how to clean your barre in preparation for painting as it is the same technique for leaving your barre as it is (this post will be available soon!!!).

Step 6: Your DIY Ballet Barre is ready to use!

Once hammered together, or glued and painted your ballet barre is ready to use. Just remember Ballet Barres are used for balance and for stretching not for hanging off or for gripping as you just might find.

DIY Ballet Barre E-Book

Why try and work it all out on your own, when I have gone and compiled everything you need to know about making a DIY Ballet Barre into a book! Check it out the e-book where we have newly designed instructional manuals, tips and advice as well as links to the video tutorials, all in one location.

ALTERNATIVE DESIGNS

If this particular ballet barre isn’t what you were after check here for the DIY Ballet Barre home page where I have instructions on how to make single ballet barres, barres from galvanized steel, and using wood. I also have a few suggestions on different styles of feet as well as on how to weigh down your barre so it doesn’t move or what to put under the feet so they don’t scratch wooden floors.